A material‑driven journey of design, connection, and large‑format 3D‑printed innovation.

Jan Jenniskens, now a master’s student at Eindhoven University of Technology, originally developed the sculptural, large‑format 3D‑printed lamp during his final year as a bachelor’s student. His vision for an interactive fixture designed to bring families closer together at the dinner table quickly made it clear that choosing the right material would be essential.

To bring his concept to life at full scale, Jan partnered with Techmer PM to engineer a transparent PETG formulation capable of delivering the clarity, structural stability, and manufacturability his design demanded. What began as a simple request for material support ultimately grew into Lumen Harmony: a powerful example of how innovative design, advanced materials, and human‑centered creativity can come together to spark connection in entirely new ways.

What Inspired the Lumen Harmony Concept?

Jan’s idea started with an important insight: family dinners remain one of the last daily moments when people gather to share time, talk, and feel connected. But this ritual is increasingly disrupted by smartphones. One notification can fracture a conversation. A quick downward glance can signal disengagement.

To address this modern tension, Jan envisioned Lumen Harmony — an interactive lamp that quietly encourages presence. The fixture’s light would act as a metaphor for connection:

- When everyone is engaged, the lamp glows warmly and consistently, symbolizing harmony.

- When someone becomes distracted by their phone, their segment of the lamp dims or turns off — a subtle, gentle cue that connection has been interrupted.

The goal wasn’t to punish or restrict. It was to create awareness.

In Lumen Harmony, light becomes a language.

Turning Concept into Form: From Sketches to Structure

Once the idea was shaped through conversations with users and experts, Jan stepped into the construction phase. He began by developing the form in CAD, refining the sculpture’s curves, geometry, and internal light paths. Initially, he explored bending large sheets of plexiglass into shape, but this method proved too imprecise for the scale and complexity he envisioned.

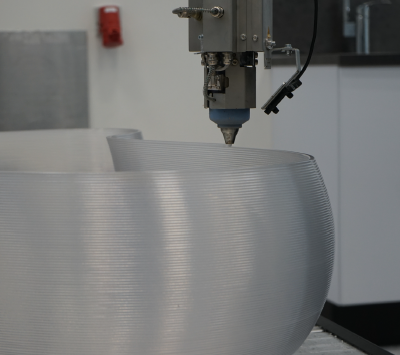

That realization pushed the project toward large-format 3D printing, a method that could produce the seamless organic form he needed with both accuracy and structural integrity.

The Search for the Right Material, and Techmer PM’s Support

To fabricate the large translucent sculpture, Jan needed a material that offered:

- Excellent light transmission

- Structural strength

- Heat stability during large-format extrusion

- A visually appealing surface finish

He consulted CEAD B.V., known for their industrial robotic-arm printers, who referred him to Fontys Brainport Industry Campus for the print and Techmer PM for high-quality transparent PETG.

Techmer PM’s HiFill® PETG 2516 wasn’t just another material choice. It was the key that enabled Jan to build Lumen Harmony at full scale with the clarity, elegance, and structural stability the project demanded.

What Makes HiFill® PETG 2516 Ideal for Large‑Format Printed Lighting?

Some of the key technical advantages of HiFill® PETG 2516 includes:

High Transparency

- Engineered for exceptional optical clarity

- Allowed lighting gradients, dimming effects, and pulses to remain crisp and expressive

Strong Mechanical Performance

- Tensile Strength: ~7,500 psi

- Flexural Strength: ~11,000 psi

- Flexural Modulus: ~325,000 psi]

- These properties ensured the lamp’s complex geometry held its shape without sagging or deformation.

Impact & Surface Reliability

- Notched Izod Impact: ~1.0 ft lbs./in

- Provided durability during machining, installation, and public exhibition.

Thermal Stability

- Heat Deflection Temperature (66 psi): ~70°C

- Crucial for maintaining dimensional stability during high temperature robotic arm printing.

Optimized for Additive Manufacturing

- Designed specifically for large format 3D printing workflows

- Delivered smooth extrusion and predictable flow, minimizing warping across large, curved surfaces

Building the Electronics and Interactive System

Alongside the physical structure, Jan engineered the embedded electronics that made Lumen Harmony truly “interactive.”

This phase included:

- Designing the internal LED system

- Programming the behavior model that responds to family interaction

- Integrating sensors that detect phone usage or disengagement

- Ensuring the light transitions were smooth, organic, and emotionally intuitive

The structure and electronics had to work in complete unity. Light was not just illumination — it was communication.

How Did Lumen Harmony Connect with the Public?

Jan debuted Lumen Harmony at Dutch Design Week, one of Europe’s leading design events. There, the project transformed from documentation into a living, interactive experience.

Visitors gathered around the glowing sculpture, watching how its shifting brightness shaped the atmosphere. Their reactions were telling:

- Families connected with the idea of light as a gentle reminder toward presence.

- Designers appreciated the fusion of emotional design and advanced materials.

- Onlookers admired the sculpture’s calming aesthetic and fluid luminosity.

The event validated Jan’s belief that light influences how people behave together — and that industrial materials can be used to create emotional experiences, not just objects.

What Made This Collaboration So Impactful?

Jan emphasized how pivotal Techmer PM’s contribution was. The donated PETG allowed him to reach a level of scale and refinement he couldn’t have achieved otherwise. The material provided:

- Structural reliability during large robotic‑arm extrusion

- Beautiful refractive properties

- Stable translucency ideal for interactive lighting

- A surface texture that unexpectedly elevated the design

Ultimately, Lumen Harmony stands as a testament to what can happen when material science and human-centered design intersect.

It is a story not only about a student project, but also about what Techmer PM empowers through its materials: creativity, emotional connection, and innovation in the next generation of designers.